| Material: | Styles 1367S, 1367FS and 1367H are stranded from pure white virgin ePTFE filament and impregnated with PTFE (an inert silicone softener/lubricant is used in style 1367S; mineral oil lubricant in 1367FS; no lubricant in style 1367H). |

| Construction: | Interwoven™ braid |

| Temperature Limit: | -400ºF to 500ºF (-240ºC to 260ºC) |

| Pressure Limit: | 250 psi for styles 1367S & 1367FS 2000 psi for style 1367H |

| pH Range: | 0 – 14 |

| Shaft Speed: | 1200 fpm (7 m/s) |

Service

Style 1367S (soft) meets specification MIL-P-24396, Type A (ships). The material is produced from pure, virgin TFE filament and carefully impregnated before braiding with a suspensoid of virgin TFE and an inert softener/lubricant for a secure bond and blocked leakage.

Recommended for rotating service in pumps, mixers, agitators and kettles, 1367FS is well suited for use with foods and pharmaceuticals. (See 1367C for an FDA compliant, heat conductive ePTFE filament packing.)

Style 1367H (hard) meets specification MIL-P-24396, Type B (ships). For high-pressure, chemical service requiring a harder material, style 1367H is manufactured in the same manner as style 1367S without the inert softener/lubricant. The result is a dense, very firm packing recommended for use in rotating service as anti-extrusion end rings (with middle rings of style 1367S) and in reciprocating service with high pressures and speeds such as in plunger pumps. The material also provides superior performance in a wide variety of filter press applications and is the industry standard for valve stems (not for high pressure steam service). Order 1367FS for FDA compliant packing.

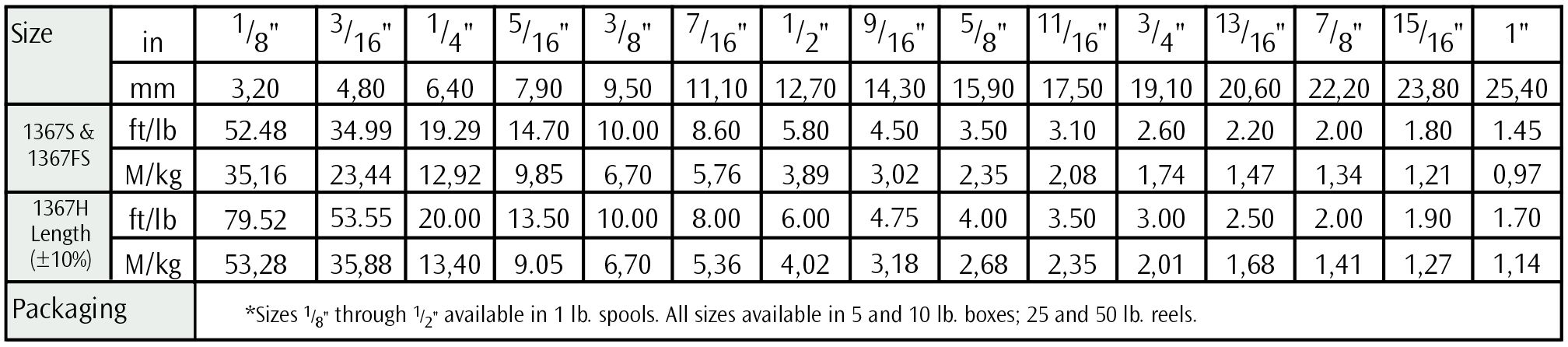

How to Order